Thermoforming is a versatile and cost-effective manufacturing process to shape plastic sheets. In this comprehensive guide, we'll explore what thermoforming is, how it works, its processes, its applications, and its benefits. Let’s start!

1. What is Thermoforming?

Thermoforming, at its core, is a dynamic plastic manufacturing process driven by heat and pressure or vacuum to transform flat plastic sheets into intricate 3D shapes with remarkable ease and cost-effectiveness.

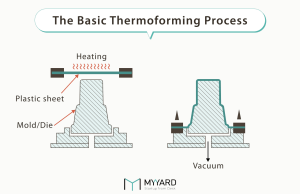

The fundamental principle of thermoforming involves heating a thermoplastic sheet until it reaches a pliable state. Once softened, the sheet is carefully placed over a mold or die, where either vacuum pressure or mechanical force is applied. This action molds the plastic into the desired shape or specification, capturing even the most intricate details with precision. Modern thermoforming machines typically integrate trimming and cutting capabilities, streamlining the production process.

Thermoforming enables manufacturers to produce high-quality plastic parts of all sizes with precision and efficiency, catering to the demands of various industries and end-users. Its ability to create complex shapes with ease and affordability makes it a valuable asset in modern manufacturing processes.

2. The Thermoforming Process

The process of thermoforming typically consists of several key steps: sheet heating, molding, and cooling/trimming.

Sheet Heating:

The process begins with a flat plastic sheet for thermoforming, usually made of a thermoplastic material such as PVC, PET, or ABS. This sheet is heated to a specific temperature, typically using radiant heaters, infrared heaters, or convection ovens. The heating softens the plastic, making it pliable and ready for molding.

Molding:

Once the plastic sheet reaches the desired temperature, it is transferred to a mold or die. The mold is typically made of metal and is shaped according to the desired final product. The heated plastic sheet is placed over the mold, and either vacuum pressure or mechanical force is applied to form the plastic into the shape of the mold.

This process may involve additional techniques such as vacuum forming, pressure forming, or twin-sheet forming, depending on the requirements of the specific application. Let’s explore more details about these techniques:

Vacuum Forming

Vacuum forming involves heating plastic sheets and draping them over a mold. Subsequently, a vacuum is applied to draw the material tightly against the contours of the mold. This process ensures a precise replication of the mold's shape on the plastic surface. The vacuum is generated underneath the sheet, gradually pulling it against the mold cavity until it conforms to the desired shape. Building prototypes via vacuum forming is relatively straightforward compared to other thermoforming methods, making it a popular choice for various applications.

Pressure Forming

Pressure forming is a thermoforming technique that applies extra pressure to shape heated plastic sheets with sharper detail and finer surface textures. Combining vacuum and positive air pressure, generates higher forming pressure, enabling the creation of intricate designs with precision. This makes pressure forming ideal for products requiring complex detailing.

Twin Sheet Forming

In this method, two separate sheets of plastic are heated simultaneously and formed using molds positioned both above and below the plastic sheets. The formed sheets are then joined together around the mold perimeter using a fused joint. Air pressure is typically injected between the sheets to facilitate bonding. Twi sheet forming excels in creating hollow plastic parts or components with double walls.

Mechanical Forming

Mechanical forming is where mechanical force, typically applied through a press or stamping mechanism, is used to shape heated plastic sheets against molds.

A core plug is commonly employed to compel the flexible plastic sheet to conform to the space between itself and the mold, resulting in the creation of surface patterns on the plastic sheet. This method is commonly employed for producing parts with intricate details or deep draws, ensuring precision and high levels of detail in the final product.

Drape Forming

Drape forming is renowned as one of the most cost-effective thermoforming techniques due to its minimal tooling requirements. In this process, a heated plastic sheet is draped over a mold, forming the desired shape. The simplicity of the method contributes to its affordability, making it an attractive option for manufacturers seeking cost-effective solutions for shaping plastic materials.

Matched Mold Forming

Matched mold forming uses molds consisting of two halves—a male and female mold—to shape a heated thermoplastic sheet. This method ensures tight seals and exceptional dimensional control, making it ideal for creating intricate shapes or patterns with precision. It finds applications in industries requiring high accuracy, such as automotive and medical device manufacturing.

Billow Forming

Billow forming is a thermoforming technique used to create hollow or rounded shapes like bottles or containers. Here, the heated plastic sheet is blown into a mold cavity using compressed air, shaping it without the need for molds.

Each thermoforming technique offers unique advantages and is chosen based on factors such as part complexity, material properties, and production requirements.

Cooling/Trimming:

After the plastic has been molded into the desired shape, it is cooled rapidly to solidify its form. This can be achieved using methods such as air cooling, water cooling, or a combination of both. Once cooled, any excess material around the edges of the formed part is trimmed away to produce the final product. Modern thermoforming machines often integrate trimming and cutting processes, streamlining production and reducing waste.

3. Thermoforming Materials

When it comes to thermoforming plastics, several materials stand out for their versatility and suitability for various applications. Thermoforming plastic sheets commonly used include:

PVC (Polyvinyl Chloride)

PVC boasts excellent strength, chemical resistance, and durability. Originating from suspension polymerization, PVC is favored in construction for its resistance to grease, fire, and impact, serving as a reliable electrical insulator. Widely used in manufacturing pipes, window frames, automotive interiors, and more, PVC offers versatility in both rigid and flexible forms. Despite its dense and water-resistant nature, PVC may react to chlorine and certain chemicals.

Common applications of PVC include construction materials, electrical conduits, signage, clothing accessories, and so on.

PET (Polyethylene Terephthalate)

PET is renowned for its exceptional clarity, toughness, and remarkable barrier properties against moisture and gases. This colorless and flexible plastic is chemically stable and exhibits high impact resistance and low gas permeability, especially with carbon dioxide and oxygen. Additionally, PET is highly recyclable and transparent to microwave radiation, though post-forming drying is required to enhance its resistance.

Widely utilized in carbonated soft drinks, mineral water bottles, synthetic fibers, and specific food products, PET remains a versatile and indispensable material in various industries.

ABS (Acrylonitrile Butadiene Styrene)

ABS, composed of acrylonitrile, butadiene, and styrene polymers, offers an impressive blend of strength, impact, and heat resistance. Its wide temperature range from -4°F to 176°F (-20°C to 80°C) allows for molding at various temperatures to accommodate diverse applications, ensuring safety under standard handling conditions. Thermoforming techniques are commonly employed by manufacturers to produce a wide array of products using ABS. From sports equipment, food containers, and automobile parts to electronic devices and piping systems, ABS emerges as a versatile material choice in today’s manufacturing.

PP (Polypropylene)

Polypropylene (PP) is a popular thermoplastic material known for its versatility in thermoforming processes. It offers a balance of stiffness, impact resistance, and heat resistance, making it suitable for various thermoforming applications.

PP is commonly used in packaging, medical devices, and consumer goods due to its excellent chemical resistance, fatigue resistance, and affordability.

HIPS (High Impact Polystyrene)

This thermoplastic material is a modified homopolymer polystyrene blended with 5-10% rubber or butadiene copolymer, enhancing its toughness and impact strength compared to pure polystyrene. Moreover, it can be easily machined and assembled using mechanical fasteners, adhesives, or solvents, further enhancing its versatility and utility in manufacturing processes.

With its cost-effective nature, toughness, and printability, HIPS is commonly used in retail countertop displays, picture frames, food containers, disposable tableware, and packaging.

PC (Polycarbonate)

PC stands out for its robustness, resilience to large plastic deformations, and not easy to crack or break. They offer exceptional strength, clarity, heat resistance, flame retardancy, and excellent electrical insulation. PC also exhibits strong chemical resistance, except to alkalis, aromatics, and hydrocarbons. Degradation begins above 140°F (60°C). The highly transparent PC material can transmit 90% of light, similar to glass, and offers customizable shades.

PC is commonly used in eyewear lenses, medical devices, automotive parts, protective gear, bullet-proof glass, safety glass, and construction materials.

HDPE (High-Density Polyethylene)

HDPE is a petroleum-based polymer known for its rigidity and exceptional strength-to-density ratio. This versatile material boasts excellent moisture resistance, and most solvents, making it ideal for packaging products with short shelf-life and various industrial and household chemicals, like detergents and shampoo. HDPE is also resistant to UV rays and water, making it durable for applications like blown bottles, containers, pipes, and plastic bags.

Heavy vs. Thin Gauge Thermoforming

Thermoforming comes in two main types: heavy gauge and thin gauge. The difference is in the thickness of the thermoforming plastic sheets used, which is a vital factor in the selection of thermoforming equipment.

Heavy gauge thermoforming handles thicker sheets, usually between .060 to .375 inches (1.5 to 9.5 mm), while thin gauge thermoforming deals with thinner sheets, less than .125 inches (3 mm) thick, fed from rolls.

| Aspect | Heavy Gauge Thermoforming | Thin Gauge Thermoforming |

| Sheet Thickness | .060 - .375 inches (1.5 - 9.5 mm) | Less than .125 inches (3mm) |

| Material Source | Sheets | Rolls |

| Thermoplastic Materials | ABS, PP | PET, PVC |

| Equipment | Cut-sheet thermoforming machines | Roll-fed thermoforming machines |

| Ideal Applications | Large parts, heavy-duty items, like car parts | Small parts, high-volume production, like food packaging |

| Production Speed | Slower | Faster |

| Production Volume | Low to medium | Medium to high |

In heavy gauge thermoforming, you work with solid sheets, making it suitable for larger, more robust products, but with slower production speed. Thin gauge thermoforming uses roll-fed material, making it ideal for smaller parts and faster production runs.

4. Thermoforming Equipment

A thermoforming machine shapes plastic sheets over objects by heating and vacuuming air, used across industries for diverse applications. However, thermoforming equipment isn't a one-size-fits-all solution. Learning how to choose the perfect type of machine for your needs is the key. Let’s explore industrial, desktop, and DIY options:

Industrial Thermoforming: Ideal for high-volume production and complex parts, industrial thermoforming machines boast large forming areas for big and intricate components. They offer deep draw capabilities to accommodate a wide range of thermoforming plastic sheet thicknesses and powerful vacuum forces for various materials. Highly automated for efficiency, they feature rapid tool-changing mechanisms but come at a higher cost due to advanced features and industrial-grade construction.

Desktop Thermoforming: Suitable for small-scale production, prototyping, or hobbyists, desktop thermoforming machines are compact with basic functionalities. While they have smaller forming areas, they are versatile for a variety of parts. They offer limited draw depth and lower force, with manual or semi-automated processes for user control. They serve as more affordable entry points compared to industrial machines.

DIY Thermoforming: A budget-friendly option for beginners, DIY thermoforming uses household tools and materials for basic experimentation. However, it has an extremely limited forming area and depth and relies on manual manipulation and improvisation. While not suitable for professional applications or high-quality production, it provides a low-cost entry point for exploring thermoforming. For example, if you want to make resin molds or chocolate molds yourself, this is the one you should go for.

| Industrial | Desktop | DIY | |

|

Production Volume |

High |

Small | Very Small |

|

Forming Area |

Large | Small |

Extremely Small |

| Automation | High | Manual/Semi |

Manual |

| Cost | Expensive | Affordable |

Very Affordable |

Unlock limitless design possibilities and accelerate your prototyping with MY YARD's desktop vacuum-forming solutions. Elevate your projects today!

5. How to Choose Thermoforming Molds

Choosing the right molds for thermoforming requires careful consideration of various factors to ensure optimal performance and efficiency.

Firstly, evaluate the production volume to determine the most cost-effective mold material. For custom parts or prototypes, which are typically low-volume, materials like wood, plaster, composites, or 3D-printed plastics are suitable, while high-volume production benefits from metal molds due to their superior durability and thermal conductivity.

Secondly, assess the complexity of the part design, opting for precision machining or 3D printing for intricate geometries.

Lastly, consider thermoforming temperature requirements and forces involved, ensuring the mold can withstand specific material types and gauges while optimizing part quality and demolding processes.

Remember, the key to a successful mold lies in understanding your project requirements. Analyze part complexity, production volume, and thermoforming conditions (temperature, pressure) to choose the most suitable material and fabrication method.

6. Benefits of Thermoforming

Thermoforming offers several advantages over other manufacturing processes, including:

Cost-Effectiveness

Compared to injection molding or machining, thermoforming stands out in terms of economy, particularly for large-scale production. Its lower tooling costs and efficient production processes contribute to significant cost savings.

Lightweight and Durable Final Products

Thermoforming crafts are lightweight yet remarkably durable products, boasting outstanding strength and resilience against impacts. This durability is owed to the unique properties inherent in thermoplastic materials used during thermoforming. These materials not only ensure longevity but also guarantee enduring performance, making them ideal for a myriad of applications.

Fast Turnaround Times

Thermoforming offers quick production cycles, ensuring speedy turnaround for finished products. Its efficient process and streamlined workflows enable manufacturers to meet tight deadlines and respond promptly to market demands. Thermoforming also facilitates rapid and cost-effective prototyping, enhancing product development efficiency and reducing time-to-market.

Design Flexibility

Thermoforming offers unparalleled design freedom, allowing for the creation of intricate shapes, textures, and surface finishes. This flexibility empowers designers to unleash their creativity, resulting in innovative and visually striking products that stand out in the market.

7. Applications of Thermoforming

Thermoforming finds extensive applications across diverse industries. Here are some common examples:

Packaging: Thermoformed trays, clamshells, bottles, jars, and blister packs are widely utilized for packaging various products, including food, electronics, cosmetics, and medical devices.

Mold Replication: Commonly used in industries like chocolate molding or resin casting, involves creating duplicates of solid objects using thermoformed molds. This technique, often associated with desktop vacuum forming, enables precise replication of shapes and details for various applications.

Automotive: Thermoformed parts can be used as interior components such as dashboards, door panels, and trim pieces.

Consumer Goods: Thermoforming is prevalent in the production of consumer and household goods, ranging from disposable cups and trays to cosmetic packaging.

Signage and Displays: Thermoforming is used to create aesthetic signage, displays, and promotional materials due to its ability to be formed into various shapes and incorporate branding elements with different textures.

Aircraft Interiors: Thermoformed plastics can be found in aircraft cabins for components like window panels, seat armrests, and overhead bins.

Medical Devices: Thermoformed trays and housings are crucial for medical device packaging, ensuring sterility and protection during transportation. Thermoforming also contributes to the production of prosthetics and orthotics, providing custom-fit solutions for patients' needs.

8. MY YARD Offers the Best Desktop Vacuum Forming Solution for Thermoforming

Thermoforming is a versatile and cost-effective manufacturing process with a wide range of applications across various industries. Whether it's packaging, automotive components, or consumer goods, thermoforming offers unmatched design flexibility, cost-effectiveness, and rapid prototyping capabilities.

Embrace the potential of thermoforming in modern manufacturing with MY YARD. From packaging to mold replication, our desktop vacuum-forming solutions offer rapid prototyping capabilities with unparalleled design flexibility. Contact us today to unlock thermoforming possibilities!

No Comments