🚀 Build a Motor-Powered Boat Using FORMART Smart Vacuum Forming | DIY STEAM Tutorial

FORMART smart vacuum forming is the perfect technology for DIY motor-powered boat manufacturing. This process is fast, cost-effective, and allows for accurate hull design verification and fluid dynamics testing. With 3D printing and laser cutting, you can quickly create an optimized boat structure. Whether you are a STEAM educator, student, or maker, this project offers a hands-on learning experience that combines creativity with engineering.

📥 Download Files for Your FORMART Vacuum-Formed Boat

✅ Download STL 3D Model File

✅ Download DXF Laser Cutting File

🛠 Equipment Needed for FORMART Smart Vacuum Forming

To successfully build your DIY motor-powered boat, you will need the following tools:

- FORMART Smart Vacuum Forming Machine – for shaping the boat hull

- FLUX Ador Laser Cutter– to cut wooden parts precisely

- Phrozen 3D Printer– for printing the mold

- Hot Glue Gun – to assemble all components

📌 Materials Required

- 2.5mm Laser-cut Wooden Board

- HIPS Plastic Sheet (Compatible with FORMART vacuum forming)

- ABS Like Photopolymer Resin

- Grease (for waterproofing)

- DC Motors × 2

- Propeller & Drive Shaft

🚀 Step-by-Step Guide

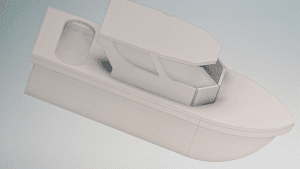

Step 1: 3D Print the Boat Mold

To begin, download the STL 3D model file and print the boat mold using a Phrozen 3D printer. Ensure the surface is smooth for a high-quality FORMART vacuum forming result.

- Download the STL 3D model file and print the boat mold using the Phrozen 3D printer.

👉

2. Ensure the surface is smooth for better vacuum forming results.

👉

Step 2: Vacuum Form the Boat Hull

Next, place the HIPS plastic sheet onto the FORMART Smart Vacuum Forming Machine. Allow the machine to heat up and start the vacuum forming process to shape the hull accurately. Finally, remove the formed hull and trim any excess material.

- Place the HIPS plastic sheet on the FORMART Smart Vacuum Forming Machine.

- Start the machine, allow it to heat up, and begin the vacuum forming process to shape the hull.

- Remove the formed hull and trim any excess material.

👉

🎯 Want to experience ultra-fast DIY vacuum forming?

🔹 Discover FORMART Smart Vacuum Forming Machine 👉 Click here for details

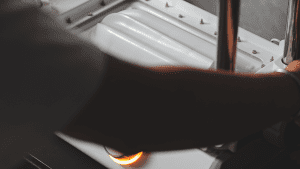

Step 3: Install the Motor System for the DIY Boat

Once the hull is formed, attach the DC motors, drive shaft, propeller, and battery holder to the boat using a hot glue gun. Adjust the weight distribution for better balance. Also, apply grease around any drilled holes and drive shaft gaps to prevent water leakage.

- Attach the DC motors, drive shaft, propeller, and battery holder to the boat hull using hot glue.

- Adjust the weight distribution to ensure stability and prevent capsizing.

- Apply grease to any drilled holes and around the drive shaft gaps to prevent water leakage.

👉

Step 4: Laser Cut the Boat Parts

Now, download the DXF laser cutting file and use the FLUX Ador Laser Cutter to cut out the deck, supports, and additional boat parts. Use a hot glue gun to assemble everything firmly.

- Download the DXF laser cutting file and use the FLUX Ador Laser Cutter.

- Cut out the deck, supports, and other wooden parts.

- Assemble the parts using a hot glue gun, ensuring a firm structure.

👉

✅ Final Step: Test Your DIY Motor-Powered Boat!

- First, place your boat in water and test its performance.

- Then, adjust the motor power and balance for optimal navigation.

👉

👉

🔥 Why Choose FORMART Smart Vacuum Forming for Your DIY Boat?

✅ Fast Production – Form a boat hull in minutes, perfect for STEAM education and makers.

✅ Cost-Effective – Uses HIPS plastic sheets, reducing manufacturing costs.

✅ High Precision – Easily replicates 3D-printed molds for a streamlined and optimized boat design.

💡 Related Reads:

🔗 How Vacuum Forming Works: Steps, Materials, & Product Ideas

🔗 How to Make an FPV Racing Track with Vacuum Forming: A Complete DIY Guide

🎯 Start Your DIY Motor-Powered Boat Project Today!

Unlock the potential of FORMART Smart Vacuum Forming Machine and start your next project!

🔹 Explore more applications 👉 Click here

🔹 Purchase FORMART Vacuum Forming Machine 👉 Buy now

🚀 Unleash your creativity and begin your Maker journey today! 🚀

No Comments