Vacuum Forming Machine

Experience excellent precision and efficiency when transforming plastic sheets into three-dimensional objects with MYYARD’s FORMART series vacuum forming machines. Our innovative technology, including unique suction control and advanced heating systems, enables you to create flawless plastic parts with ease. The user-friendly interface also has plenty of adjustable settings, offering versatility to beginners and professionals alike. Unleash your creativity with our smart and powerful desktop vacuum formers today!

Why Choose MYYARD Vacuum Former?

By incorporating innovative features for optimal effects and easy operation, MYYARD’s desktop vacuum forming machines can empower you to achieve outstanding results on every project. Plus, our commitment to quality ensures great durability for long-lasting performance.

Unique Suction Control Technology

FORMART series vacuum forming machine features a powerful, industrial-grade suction power of up to -90 kPa. It also leverages advanced vacuum sensors and flow control technology to let you fine-tune the vacuum levels for your specific project requirements.

Even if you are unfamiliar with the settings, FORMART offers three preset suction modes, so you can just press the button and let our intelligent machine take care of the complicated parameters.

Comprehensive Materials Database

Our vacuum former has an extensive built-in materials database, offering compatibility with a wide range of plastic materials, including original FORMART series materials and third-party plastic sheets. Additionally, our machines can store up to five custom settings, enabling you to optimize parameters for your preferred materials.

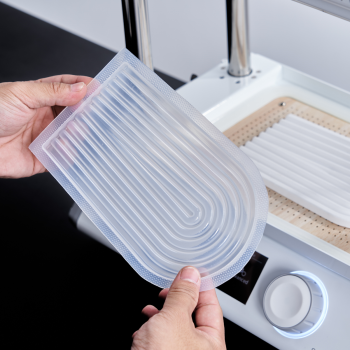

Exclusive Plastic Sheet Dehumidifying System

Say goodbye to frustrating air bubbles with FORMART’s exclusive plastic sheet dehumidification technology! This built-in system effectively removes moisture from the plastic sheet before forming, resulting in flawless, professional-quality parts.

Intelligent Preheating Program and Rapid Heating

FORMART desktop vacuum former uses industrial-grade carbon fiber quartz heating tubes, so it heats up three times faster than conventional machines. Paired with our built-in smart preheating program, it ensures consistent temperature distribution and superior forming quality for various materials.

Quick Locking Frame for Efficiency

Our patented quick-locking frame allows you to securely lock the plastic sheet in place, simply by turning the fast-locking handle. The ability to stop at any height further enhances efficiency, enabling quick sheet changes without removing the mold.

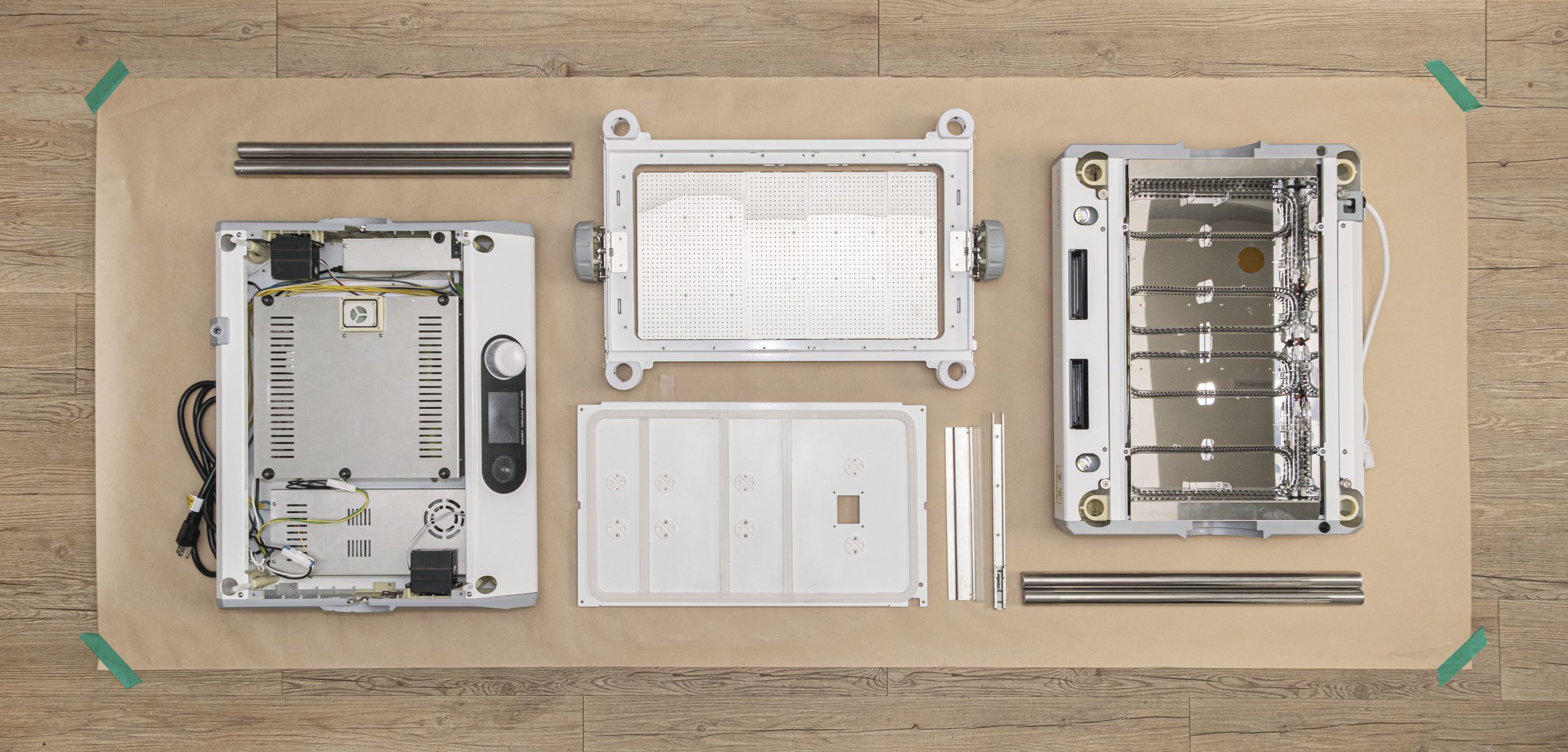

Modular Design for Simple Maintenance

MYYARD’s FORMART series vacuum formers feature a modular design, allowing you to easily remove faulty modules for effortless maintenance. Once the machine is turned on, its self-diagnostic system will pinpoint any issues for quick and accurate troubleshooting. Then, you can remove it and send it back for repair!

Quality Assurance with Two-Year Warranty

Our FORMART desktop vacuum forming machines are 100% made in Taiwan and rigorously tested to meet the highest quality standards. The machines are also backed by SUD-TUV certification, guaranteeing safety, durability, and exceptional performance. Moreover, we offer a two-year warranty on core components, reflecting our commitment to excellence.

How to Use Our Desktop Vacuum Former

It is easy to create unique plastic objects with MYYARD’s desktop vacuum former, all it takes is three simple steps!

Step 1. Prepare a Mold

Almost anything can be used as a mold, including 3D prints, sculpted clay, wooden toys, metal pieces, and even natural objects, like pine cones or seashells, your imagination is the limit! Just make sure the mold is not wet or dusty before you place it on the vacuum former.

Step 2. Select Vacuum Former Settings

Insert your plastic sheet into the vacuum forming machine, then set the suction power and heat settings. If you can’t decide on your own, select a mode from our presets to let the smart vacuum former handle the complexities. These settings will ensure optimal vacuum pressure and even heating.

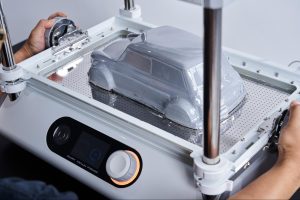

Step 3. Form the Plastic

Gently lower the heated plastic sheet onto your mold. Our vacuum former will replicate the design with speed and accuracy, and once the plastic cools down, you can remove it from the mold and enjoy the results!

Applications of FORMART Desktop Vacuum Forming Machine

Tired of the lengthy production times, high costs, and bulky equipment that come with traditional molding?

Whether it's for culinary creations, architectural models, or other applications,

FORMART vacuum former allows you to bring your ideas to life in a quick, affordable, and convenient way!

Food

Elevate your culinary artistry with custom-made chocolate, jelly, or fondant molds.

You can also create stunning presentation trays, food containers,

and even unique beverage cups using FORMART!

Packaging

Our vacuum forming machine lets you create boxes, lids, trays, or containers

tailored perfectly to your product’s dimensions.

To enhance your product presentation,

you can also create eye-catching blister packaging.

Arts & Crafts

Vacuum formers allow you to showcase your creativity

with unique molds for your DIY candles, soap, and resin.

Custom paint pallets, scale models, and tabletop games

are also some of the fun things you can create with FORMART.

Product Design

FORMART allows you to prototype your product ideas

with precision and efficiency.

Create detailed models for these products and

showcase their designs during your next presentation!

Architecture & Interior Design

FORMART enables you to visualize concepts with

detailed scale models and functional concrete molds

for interior designs and architectural prototypes.

Home Decor

Transform your space with custom-designed lighting fixtures,

beautiful wall panels, and special signage displays

using our vacuum forming machine.

Cosplay

Our vacuum forming machine lets you create costumes

with custom masks, props, and accessories,

bringing your favorite characters to life with stunning detail.

Gardening & Landscaping

Decorate your garden with vacuum-formed creations,

such as DIY planters, seed trays, and more!

Vacuum Forming Machine FAQ

1. What is vacuum forming?

Vacuum forming is a process that uses heat and vacuum pressure to shape plastic sheets into desired forms. It's a versatile method for creating various products, including packaging, molds, and product prototypes.

2. What is the difference between vacuum forming, pressure forming, and thermoforming?

Thermoforming is the broad term used to describe plastic shaping processes, which encompasses both vacuum and pressure forming. These two methods use different techniques to mold heated plastic into 3D products. Vacuum forming uses suction to draw heated plastic onto a mold, making it ideal for simple, single-sided parts. On the other hand, pressure forming employs air pressure to mold both sides of a plastic sheet, resulting in products with greater detail.

3. What types of materials can be used in vacuum forming?

Vacuum forming accommodates a wide range of plastics materials, including polyethylene terephthalate (PET), high impact polystyrene (HIPS), low-density polyethylene (LDPE), and thermoplastic polyurethane (TPU). Each material has their own unique properties, so be sure to consider your desired product thickness, surface transparency, and budget when selecting plastic sheets for vacuum forming.

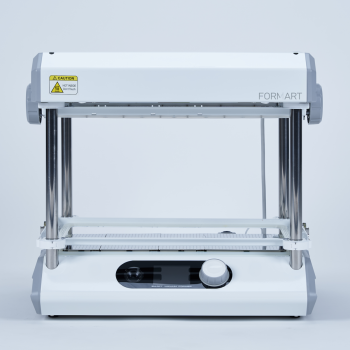

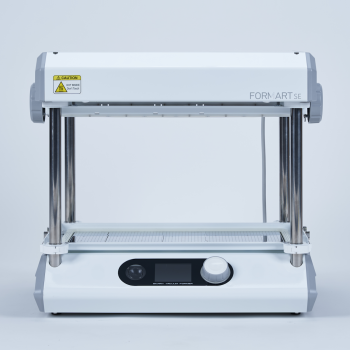

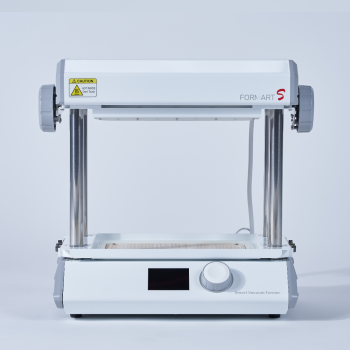

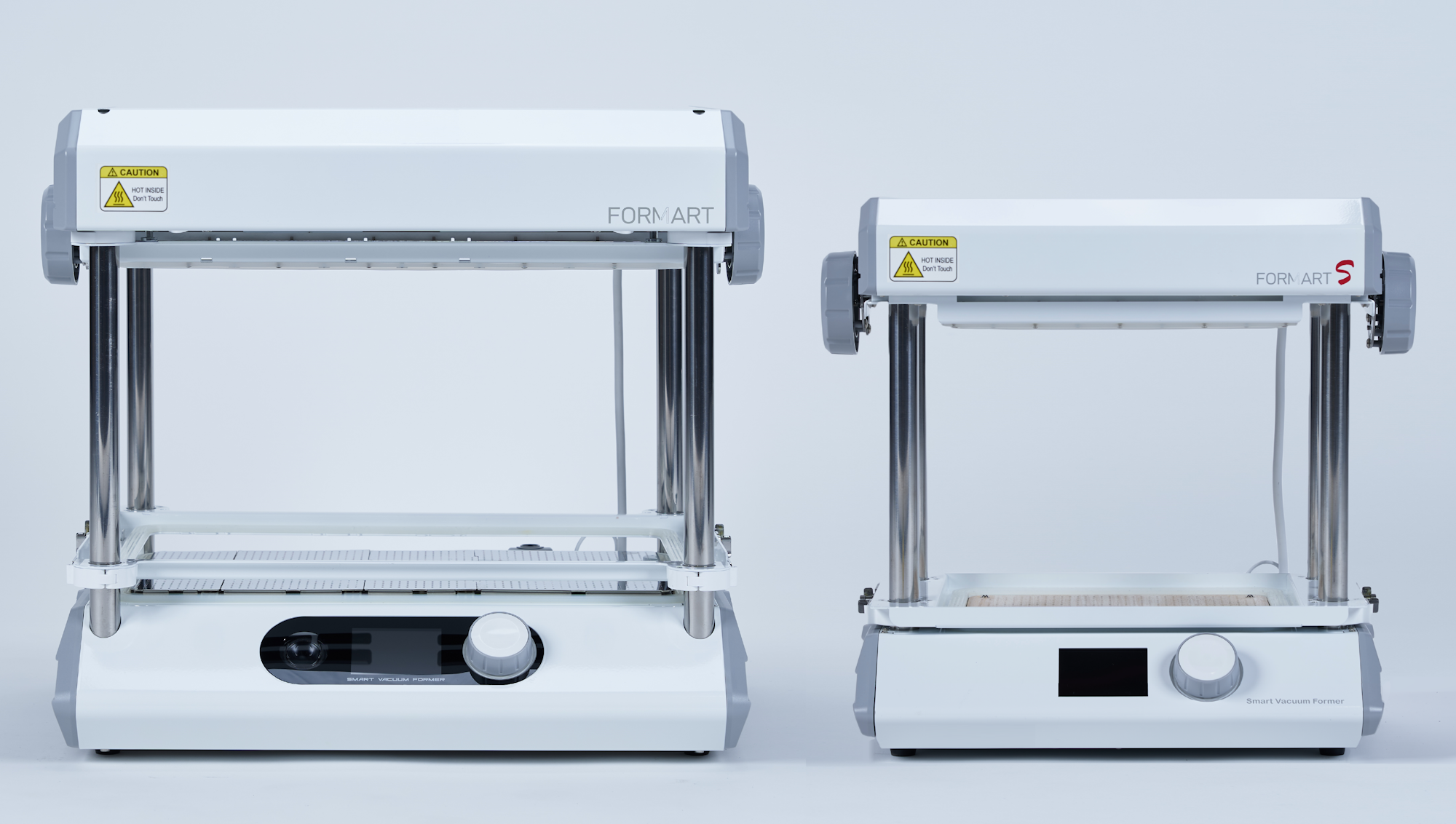

4. Which FORMART plastic vacuum forming machine suits you best?

This depends on your specific needs. You can compare our vacuum forming machines’ specifications with the table below to find the ideal fit for your projects.

| Model |

FORMART 2 |

FORMART SE |

FORMART S |

| Display |

3.5” 480*320 Full Color LCD |

||

| Machine Size | 63(W) x 53(H) x 48(D)cm | 63(W) x 53(H) x 48(D)cm | 50(W) x 46(H) x 31(D)cm |

| Machine Weight | 25kg | 24kg | 13kg |

| Power Supply |

|

|

|

| Max. of Draw |

16cm |

||

| Heater Type |

Quartz heater tubes |

||

| Temperature Range |

90-230°C |

||

| Sheet Size |

Accommodates 4 sizes:

|

Accommodates 4 sizes:

|

Accommodates 1 size:

|

| Sheet Thickness |

0.3-3.0mm |

||

| Pump Type | DC brushless pump + AC induction pump | DC brushless pump + AC induction pump | AC induction pump |

| Suction Mode | -90KPA with adjustable pressure | -90KPA with 3-step settings selection | -90KPA with adjustable flow rate |

| Additional Features |

|

|

|

Get the Best Vacuum Forming Machines at MYYARD

MYYARD offers the perfect solution to transform your ideas into reality. From innovative features, such as advanced suction control, rapid heating, and built-in dehumidification, to exceptional quality and user-friendly operation, our vacuum forming machines empower you to effortlessly create professional plastic objects, whether you're a hobbyist, entrepreneur, or established business. Explore MYYARD’s vacuum formers today!