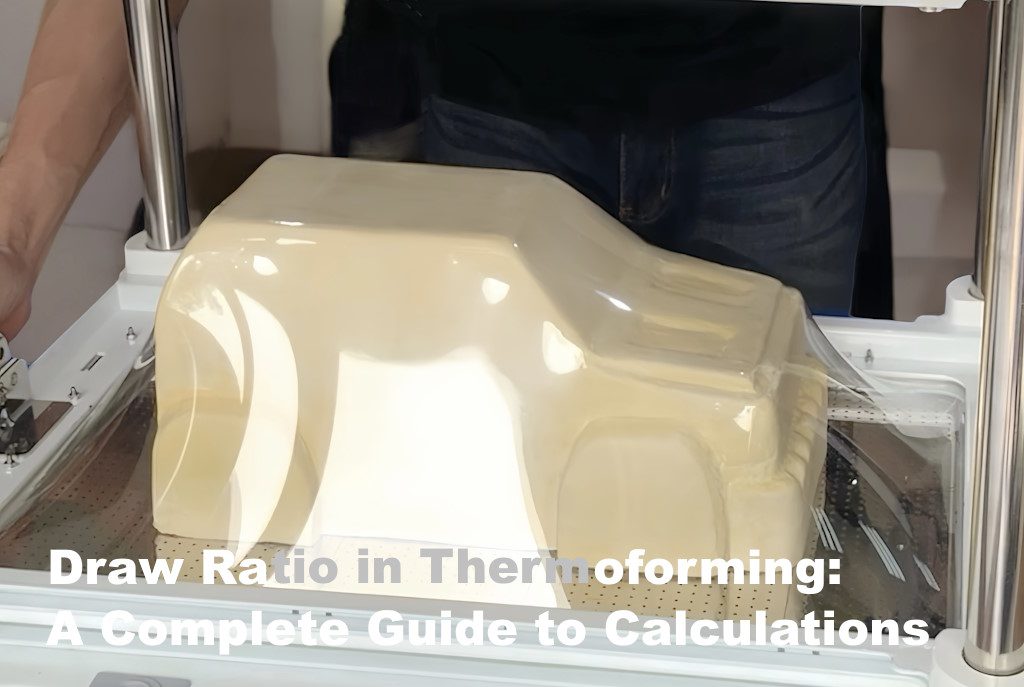

In thermoforming, the draw ratio is a crucial metric that determines the optimal thickness of the plastic sheet required for creating high-quality parts. By calculating the draw ratio, manufacturers can ensure uniform wall thickness, minimize material waste, and achieve their final products' desired strength and durability.

What is the Draw Ratio in Thermoforming?

In thermoforming, the draw ratio is a key calculation that helps determine the minimum thickness of the plastic sheet needed to form a part. It is calculated by dividing the surface area of the mold by the footprint of the heated plastic sheet. This ratio ensures that the plastic stretches evenly during the molding process, resulting in a uniform wall thickness. By using the draw ratio, manufacturers can choose the right starting thickness of plastic to avoid material waste while still achieving the desired part strength and quality.

How to Calculate the Draw Ratio in Thermoforming Step-by-Step

Calculating the draw ratio is key to achieving uniform wall thickness and optimal material use in thermoforming. Here, we simplify the process to help you select the ideal plastic sheet thickness.

Step 1: Measure the Mold’s Surface Area

Start by calculating the total surface area of the mold.

For example, if the mold measures 9" wide, 11" long, and 4" high, the surface area would be the sum of all sides and the top: 2(9" x 4") + 2(11" x 4") + (9" x 11") = 72" + 88" + 99" = 259".

Step 2: Calculate the Plastic Sheet’s Footprint

Next, calculate the footprint, which is the area of the heated plastic sheet. In this case, the footprint is 9" x 11", which equals 99".

Step 3: Determine the Draw Ratio

Finally, divide the surface area by the footprint to get the draw ratio: 259" / 99" = 2.62.

This ratio helps you determine the appropriate thickness of the plastic sheet for uniformity and strength.

Use the Draw Ratio to Determine the Minimum Starting Gauge

Once you’ve calculated the draw ratio, you can use it to find the minimum starting gauge of your plastic sheet. Multiply the draw ratio by the desired finished thickness.

For example, with a draw ratio of 2.62 and a target final thickness of 0.120, the calculation would be 2.62 x 0.120" = 0.314.

This means you’d need to start with a sheet of at least 0.314" to achieve your desired final thickness.

What Affects the Draw Ratio in Thermoforming?

The draw ratio in thermoforming is influenced by how much the plastic sheet stretches over the mold. As it stretches, the sheet becomes thinner, affecting the wall thickness of the final product. Selecting a sheet thick enough to maintain strength without thinning excessively is crucial, though overly thick plastic can drive up material costs. Striking the right balance between sheet thickness and efficiency is essential to ensure quality and cost-effectiveness.

Mold temperature is another critical factor. If the mold temperature is too low, the sheet may not stretch sufficiently, resulting in incomplete coverage and an increased risk of uneven wall thickness. Proper mold heating promotes even material distribution across the surface, reducing stress points and improving the overall product quality. Maintaining an optimal mold temperature helps minimize stretching resistance, ensuring consistent and stable results throughout the thermoforming process.

Unlock Thermoforming Potential with MY YARD's Superior Desktop Vacuum Forming Solutions

Understanding the draw ratio in thermoforming is essential for achieving optimal material use and product quality. By accurately calculating the draw ratio, manufacturers can ensure uniform wall thickness and minimize waste, enhancing the efficiency of their production processes.

For those looking to harness the power of thermoforming, MY YARD offers the best desktop vacuum-forming solution tailored for various applications. Our innovative technology allows you to explore unmatched design flexibility and rapid prototyping capabilities. Embrace the future of manufacturing with MY YARD's vacuum-forming machine—visit our product page today to unlock endless thermoforming possibilities!

Related Articles Suggested for You:

Thermoforming Explained: Process, Materials, and Applications

How to Make Resin Molds at Home: DIY Step-by-Step Guide

How to Make Chocolate with Molds DIY: Mold Types, Tips & More

What is Vacuum Forming: Steps, Materials, Types with Pros & Cons

No Comments