Vacuum forming, a type of thermoforming, is a versatile and accessible manufacturing process that allows you to shape plastic sheets into a variety of forms by applying heat and vacuum pressure. Whether you’re a hobbyist, a small business owner, or working in product development, vacuum forming opens the door to a multitude of creative possibilities. Here are ten unique vacuum-forming project ideas to inspire your next creation.

1. Custom Chocolate Molds

Who doesn’t love chocolate? With vacuum forming, you can take your sweet tooth to the next level by creating custom chocolate molds. Whether you’re designing your own initials, animal shapes, or intricate patterns, vacuum forming allows you to mold chocolate into truly unique treats. Perfect for parties, gifts, or even starting your own small chocolate business! Pro tip: experiment with fillings like caramel or nougat for added fun.

2. Home Décor Items

Add a personalized touch to your home with vacuum-formed trays and mirrors. You can craft chic, modern pieces like minimalist trays for jewelry or keys, moon lamps, or even design custom mirrors to reflect your style. Vacuum forming makes it easy to replicate shapes consistently, so you can create matching sets or themed home décor. Plus, it’s a great way to use recycled plastic for a sustainable edge.

3. Prototype Packaging

If you’re developing a product and need packaging, vacuum forming is a lifesaver. Create your own packaging prototypes right at home, whether for electronics, cosmetics, or small gadgets. Not only does this cut down on costs, but it allows you to rapidly test different designs, like a clamshell packaging.

4. Custom Ice Cube Trays

Throw a party with a twist by serving drinks with custom ice cubes! Using vacuum forming, you can design and produce ice cube molds in any shape you desire, from logos and letters to fun shapes like stars or hearts. It’s a playful, creative touch for special events that will leave guests talking. The best part? The molds can be reused for gelatin desserts or chocolates.

5. Soap and Candle Molds

If you love handmade soaps or candles, why not make your own custom molds? Vacuum forming lets you create intricate and reusable molds that you can use over and over again. Whether you're crafting animal-shaped soap bars or geometric candles, this process allows you to explore your creativity and design eye-catching products. Perfect for hobbyists or anyone starting a small business.

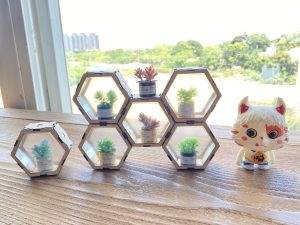

6. Geometric Terrariums

Add a bit of green to your home with a vacuum-formed terrarium! You can create geometric terrariums or display boxes that are perfect for displaying succulents or air plants. Form the plastic shell for the top and mold a concrete or plastic base to hold the plants. These stylish and modern designs bring a sleek look to any room and can be customized to fit your space.

7. Custom Face Shields and Masks

Whether for safety or fun, like the Halloween event, vacuum forming can help you design custom face shields or masks. Cosplayers can benefit from this technique by crafting intricate masks or armor pieces with precise details, all without needing expensive tools. If you're interested in creating unique PPE, vacuum forming allows you to produce face shields quickly and efficiently, adding personalization for comfort and fit.

8. Blister Packaging for Small Products

Have you ever needed packaging for small items like beads, batteries, or craft materials? Vacuum forming is perfect for creating blister packaging that holds items securely in place. You can even design customized shapes for toys, tools, or jewelry, ensuring your products look professional and well-presented. This is especially handy for small businesses that need low-cost, on-demand packaging solutions.

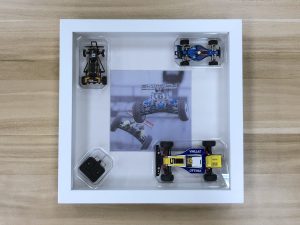

9. Concrete Molds for Clocks and Home Accessories

Love working with concrete? Vacuum forming is a great way to make custom molds for concrete projects. You can create planters, clocks, photo frames, or coasters by forming a sturdy plastic mold and pouring concrete into it. The smooth, clean lines of vacuum-formed molds make your concrete pieces look polished and professional, and it’s a great way to explore industrial design at home.

10. Custom Toy Parts and Prototypes

For toy designers or enthusiasts, vacuum forming offers a fast way to prototype toy parts. Whether you’re making custom action figures, cute figurines, dolls, or board game pieces, vacuum forming allows you to create durable parts with complex designs. Once you have the molds, you can experiment with different plastics, paints, and finishes to bring your toy designs to life.

Unlock Endless Creative Potential with MY YARD’s Innovative Vacuum-forming Machine

With vacuum forming, the possibilities are endless! Whether you’re making personalized chocolates, home décor, or even working on your own line of products, this versatile process allows you to create detailed, professional-quality items from the comfort of your home or workshop. Get creative, experiment with different materials, and enjoy the satisfaction of bringing your ideas to life!

Take your manufacturing to new heights with MY YARD’s Vacuum Forming Machine. Whether you're producing custom packaging, developing resin molds, or exploring innovative designs, our cutting-edge desktop vacuum-forming technology offers unmatched flexibility for rapid prototyping. This solution is ideal for small businesses, hobbyists, or manufacturers looking for an affordable, efficient way to create high-quality, durable products. With MY YARD, you can streamline your production process, ensuring precision and cost-effectiveness every step of the way.

Don’t wait! Contact us today to discover how our systems can revolutionize your production process!

Related Articles Suggested for You:

Thermoforming Explained: Process, Materials, and Applications

How to Make Resin Molds at Home: DIY Step-by-Step Guide

How to Make Chocolate with Molds DIY: Mold Types, Tips & More

What is Vacuum Forming: Steps, Materials, Types with Pros & Cons

No Comments