作者:MakerPRO/蔡松寰

塑膠依照其特性,大致可分成兩大種類 — 熱塑型與熱固型,而我們使用在真空成型機上的,屬於熱塑性塑膠,這是因為真空成型機的基本原理便是將塑膠加熱軟化後,利用真空的吸力將塑膠板塑形,冷卻後就定形了。

然而常見的塑料種類五花八門,到底在選用塑料版時有甚麼需注意的呢?塑料板又有哪些種類與特性呢?相信許多人都有不少類似的問題浮現在腦海之中,接下來我們將介紹常見回收代碼 1~7 號的塑膠,並說明一些塑料板的小知識。

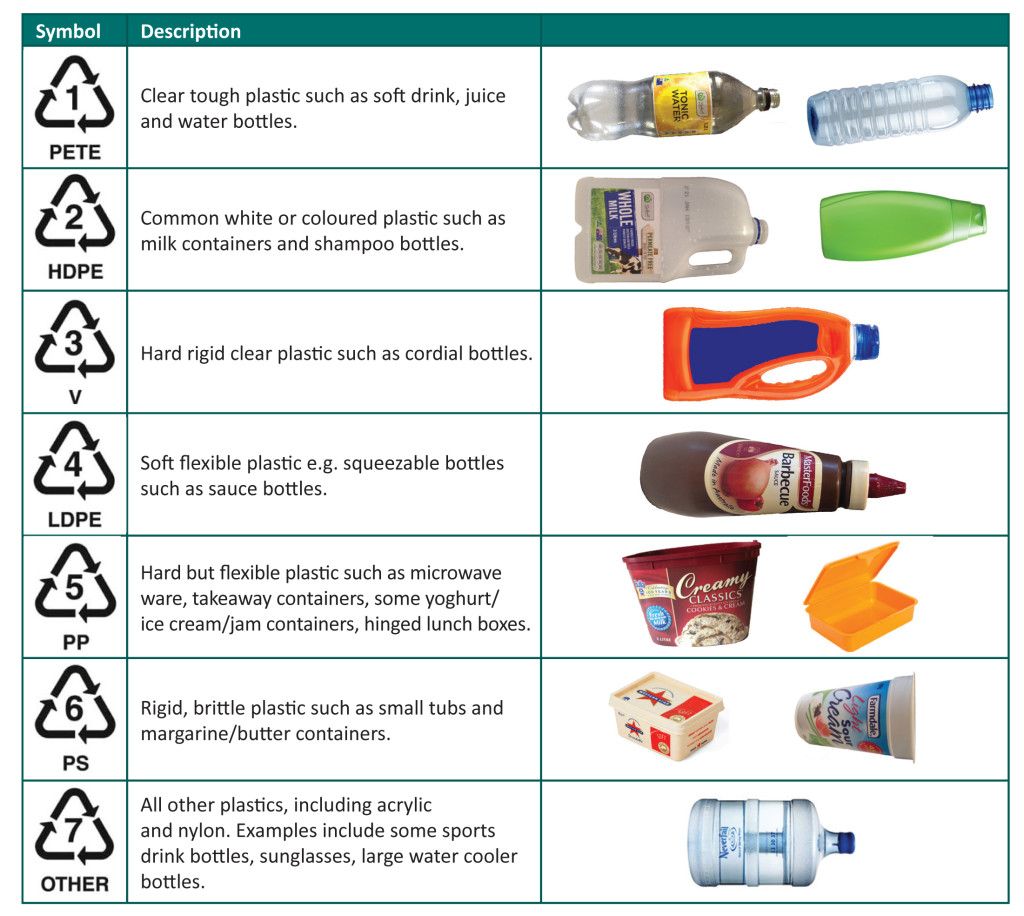

認識可回收塑料分類

塑膠回收的七種分類(圖片來源:KS Environmental Group)

1. PET/PETE(聚乙烯對苯二甲酸酯)

- 耐熱溫度:60~85 °C

- 特性:耐酸鹼,硬度佳韌性佳,質輕且不易揮發

- 生活應用:我們見的寶特瓶即是 PET,在超過耐熱溫度或是使用過久的狀況下,會釋出添加在內的塑化劑,但是一般的情形下 PET 並不會添加塑化劑

2. HDPE(高密度聚乙烯)

- 耐熱溫度:90~110 °C

- 特性:耐腐蝕、耐酸鹼

- 生活應用:算是生活上應用最廣的塑膠,舉凡購物袋、鮮奶瓶皆是此類

3. PVC(聚氯乙烯)

- 耐熱溫度:60~80 °C

- 特性:含氯塑膠,多用於工業產品,從生產、使用到廢棄處理,都會產生有毒物質

- 生活應用:常見的灰色水管以及一些調味罐是用 PVC 製成,其製程必須添加諸多塑化劑來改善其一些性質,高溫容易釋放出塑化劑,所以環保署逐步禁用中

PVC 因為便宜、製造方便,廣泛存在於我們的生活周遭,但其製程會釋放出大量塑化劑,被國際綠色和平組織稱為「毒塑膠」(圖片來源:bob vila)

4. LDPE(低密度聚乙烯)

- 耐熱溫度:70~90 °C

- 特性:耐腐蝕、耐酸鹼,過熱易產生致癌物

- 生活應用:塑膠袋以及各種實驗室用的藥瓶、洗瓶或是保鮮膜等

5. PP(聚丙烯)

- 耐熱溫度:100~140 °C

- 特性:耐酸鹼、耐化學物質、耐高溫、耐碰撞

- 生活應用:諸多食物容器、餐具、水杯等,如果說食品最常用的塑料版是 PP 當之無愧,因為其在一般食品處理的溫度範圍內,不太會釋出有害物質,且其耐衝擊的特性,在工業上也應用廣泛

6. PS(聚苯乙烯)

- 耐熱溫度:70~90 °C

- 特性:吸水性低,安定性佳

- 生活應用:養樂多瓶、泡麵碗等,發泡後就是我們常見的寶麗龍

常見的養樂多瓶由聚苯乙烯製成(圖片來源:bloomberg)

7. Other

其他不屬於上述分類的都直接歸類為 7 號

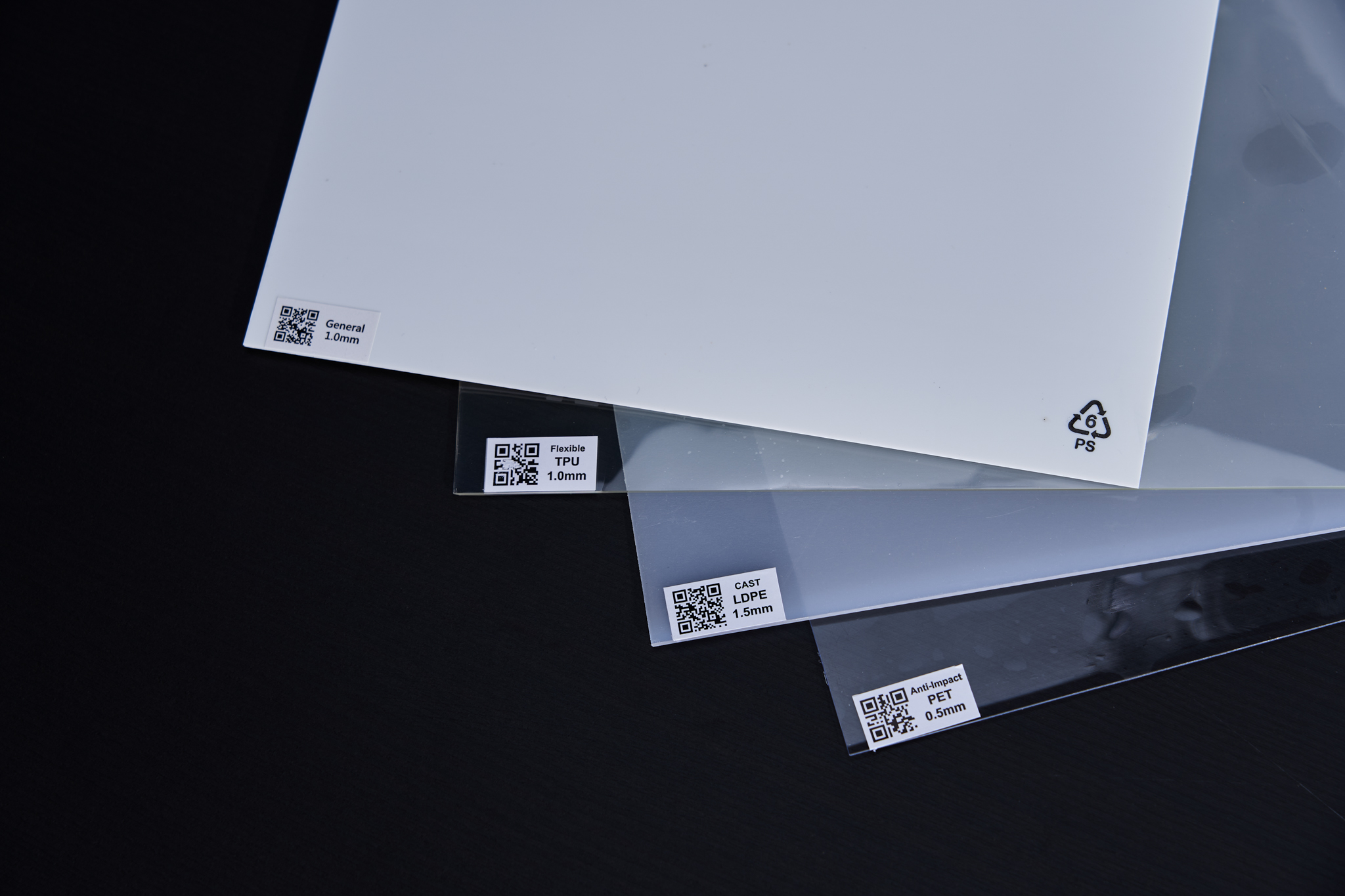

FORMART 適用塑料

智慧真空成型機 FORMART 的開發商邁雅設計對環保議題相當重視,雖然各種熱塑性塑料大多可用於真空成型的製程,但該團隊為避免這設備對環境造成太大衝擊,因而在眾多板材中挑選兼具熱塑性及環保性的塑料板,要求具備無毒、容易回收的環境友善特性。此外,該團隊搭售的每張塑膠板,還會在其四個角落都貼上環保回收標示,讓回收人員一目了然,不致於成為燒或埋掉的垃圾。

以下為四款 FORMART 選用的環保塑料類型、特性及適合用途:

1. 食品級塑膠板–PP

無毒性、無臭味 PP(聚丙烯 Polypropylene)板,具備絕佳的抗化學腐蝕特性以及耐彎折特性,能夠長時間耐受 120 ℃,是做為各種食品應用的絕佳選擇。

- 應用:巧克力或軟糖模具、食品壓模、布丁盒、食品容器(可微波)

- 回收分類:5 號塑膠

- 顏色:白

- 尺寸:50 cm x 30 cm;A4

- 厚度:0.5 mm、1.0 mm

2. 耐衝擊塑膠板–PET

耐衝擊 PET(聚對苯二甲酸乙二酯 Polyethylene terephthalate)板,具有高透明度與耐衝擊特性,特別適合需要高透明度與高衝擊強度的產品類應用。

- 應用:包裝泡殼、玩具外殼、托盤、食品包裝、低溫食品容器

- 回收分類:1 號塑膠

- 顏色:透明、白、灰、黑

- 尺寸:50 cm x 30 cm;A4

- 厚度:0.3 mm、0.5 mm

3. 泛用型塑膠板–HIPS

高強度 HIPS(高密度聚苯乙烯 High impact polystyrene)板,具備特別優秀的成型及尺寸安定特性,外表容易上色,適合各種翻模或需要上色的產品類應用。

- 應用:實體翻模、皂模、面具、Cosplay 道具、模型配件

- 回收分類:6 號塑膠

- 顏色:白

- 尺寸:50 cm x 30 cm;A4

- 厚度:0.3 mm、0.5 mm、1.0 mm

4. 特殊板系列–TPU 軟板

軟性 TPU(熱塑性聚氨脂 Thermoplastic polyurethanes)板,質地柔軟、無毒,可在自然環境中分解的特性,適合用來做為脫模較為困難之翻模替代材料,或其他需要軟性材質之應用。

- 應用:實體翻模(有倒勾可)、3C 產品保護殼

- 回收分類:一般垃圾

- 顏色:透明

- 尺寸:A4

- 厚度:1.0 mm

- 硬度:80A

小結

塑膠的種類多,用途也廣,在使用真空成型機之前,除了考慮塑形時的效果外,也該多想想這塑料最終廢棄時,是否會對環境帶來衝擊。FORMART 創辦人史承彥受訪時曾強調,若是這台設備只能「生產」卻不夠「環保」,他也不會願意將它帶到更多人的手上,而為了這個對環境負責的訴求,他和團隊花了很多時間去學習塑料特性,並挑選出兼具可塑性和安全無毒、環保無害的板材,可說是承擔社會企業責任的表率,值得肯定。

No Comments